Festool TSV 60 Kebq-plus review

With so many plunge saws on the market, does the Festool TSV 60 KEBQ-Plus have anything new to offer? Jonathan Salisbury takes a look

Having previously used a table saw for all my cutting, discovering the track saw was a revelation. Even with two people, manipulating a full-size piece of 18mm plywood onto a table and keeping it up to the fence was quite a task. Clamping an aluminium track and running a small circular saw along it was something that I didn’t need help with.

Track saws are available to suit all budgets. I’ve tried a few over the years; some motors are smoother than others, the quality of materials and finish varies, and the more expensive models are easier and more enjoyable. What makes the biggest difference, however, is a decent quality, sharp blade to match the material being cut.

First impressions Festool TSV 60 Kebq-plus

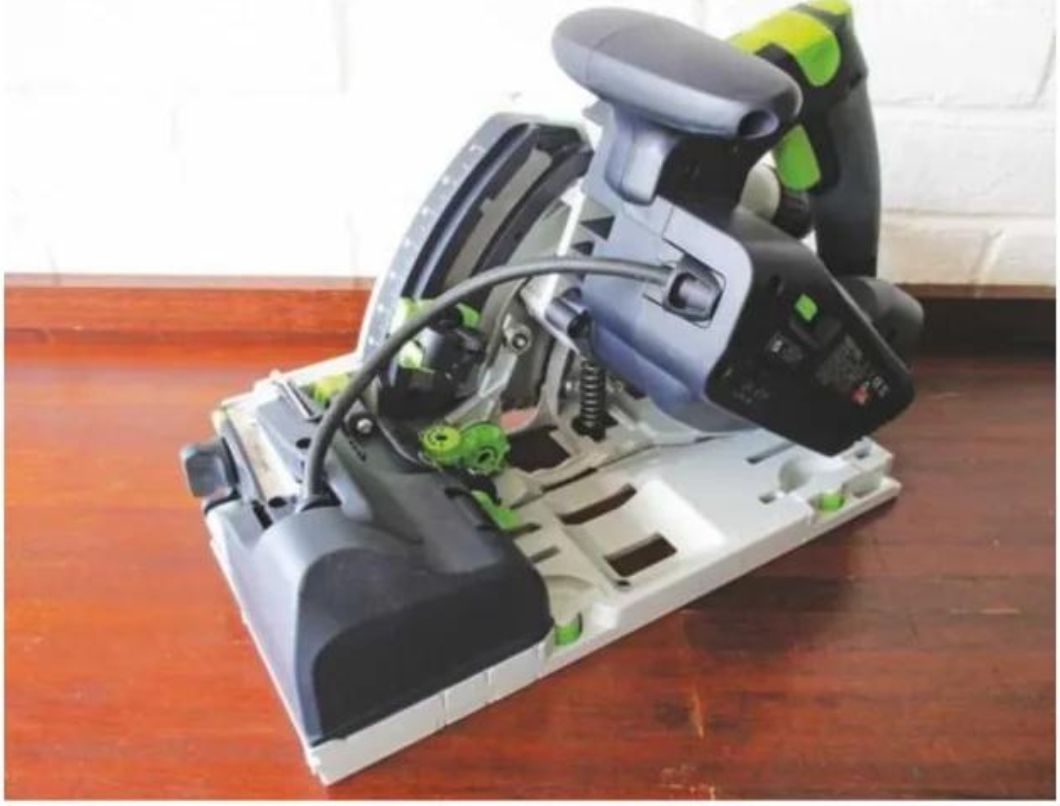

The Festool TSV 60 KEBQ-Plus plunge-cut saw with scoring function takes track saws to another level. It looks more complex, with a secondary unit located on the front and a host of levers, knobs and dials. The shape is functional, flat-sided, with curves seemingly only where required. Handles are well positioned and provide comfortable grip; there’s a socket for the removable power cord and a rotatable dust extraction port at the unit’s rear, which allows the hose to be suitably positioned. Underneath this is a small clip, which prevents the cable catching on the work surface.

… a removable, locking power cable…

… and an adjustable dust port

A dedicated clip keeps the cable organised

The iconic Festool bright green trigger stands out

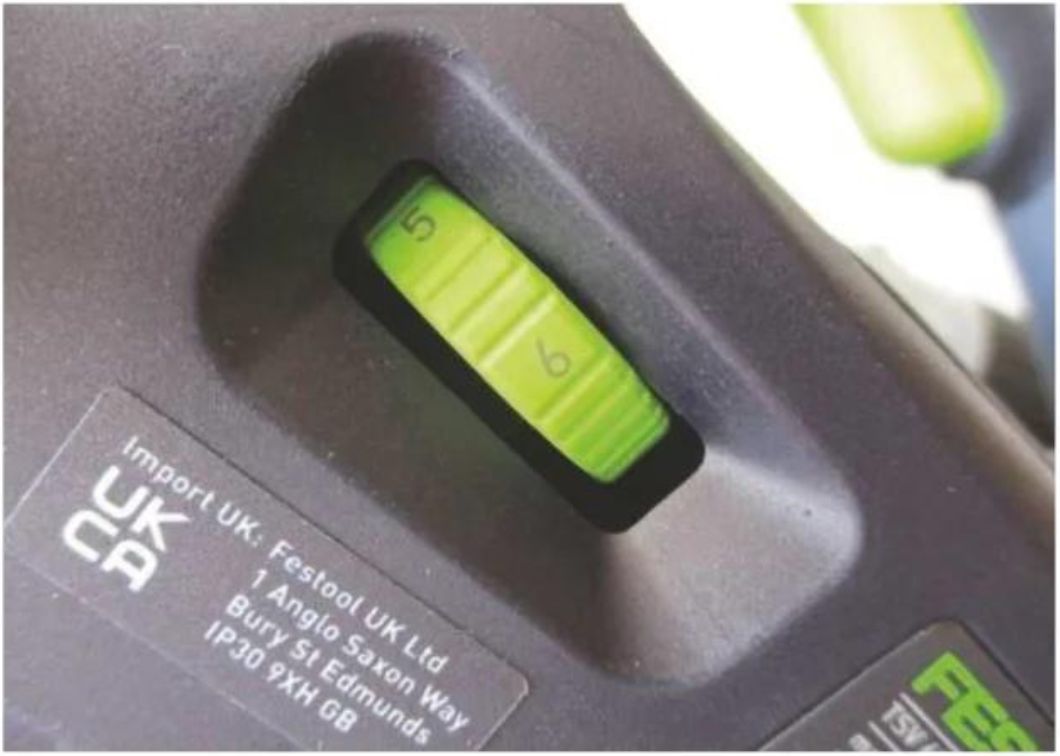

Controls are all bright green – the on-off trigger, adjustment knobs, power cable lock ring, safety catches, depth gauge pointers, the FastFix lever that aids blade replacement, along with the blade rotation speed dial. A hex key for the saw blade screw is kept under the FastFix lever, and another smaller one, for the scoring blade, is located at the front.

What’s the problem?

The main disadvantage with track saws is that the blade rotates anti-clockwise, meaning the teeth move in an upwards direction when breaking through the top surface. This causes wood splintering, or chipped edges to laminated tops. Cutting with the upper surface down can solve this issue, but then you can’t monitor progress; a thin, sacrificial board clamped to the top, thick tape or a pre-cut line all require preliminary work and aren’t always a guarantee that things will go your way. Alternatively, you could over-cut slightly and rout back to the line; two machines, two setups, two chances for things to go wrong, not to mention taking twice the time.

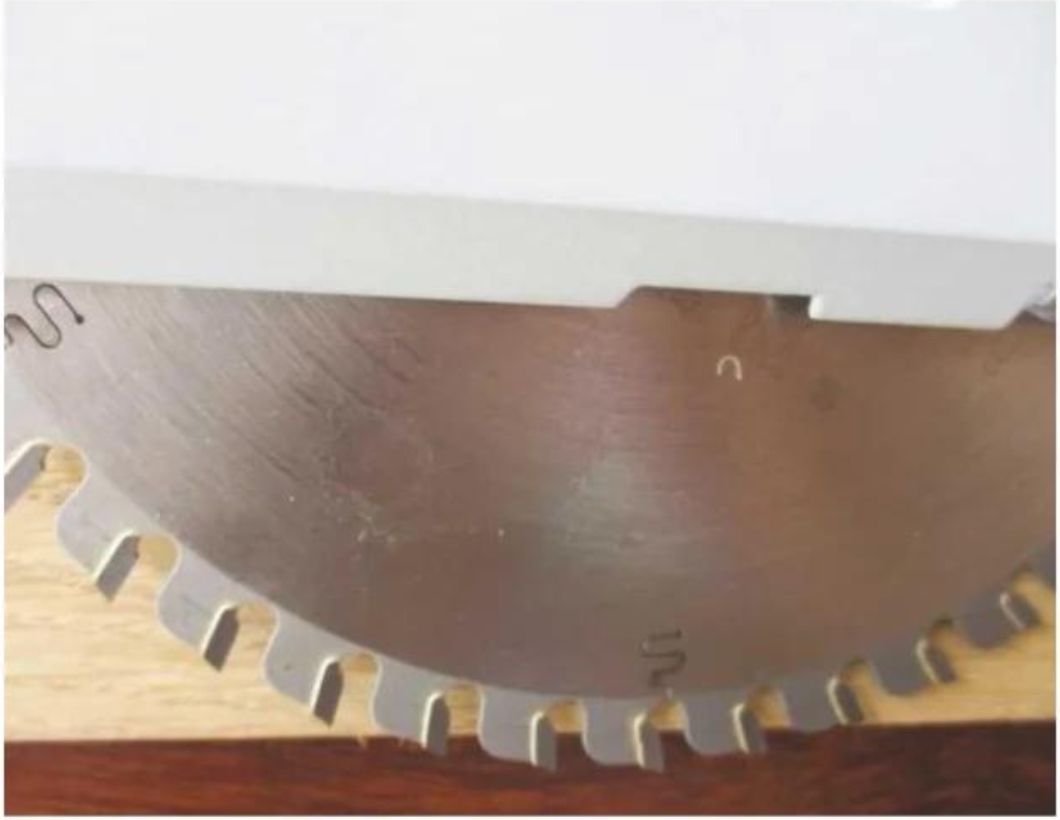

The TSV 60 KEBQ’s main saw blade works in the same way as any other track saw, but with an additional, faster-spinning diamond-faced scoring wheel located in front; by pre-cutting a blade-width channel, there are no edges to chip.

Testing

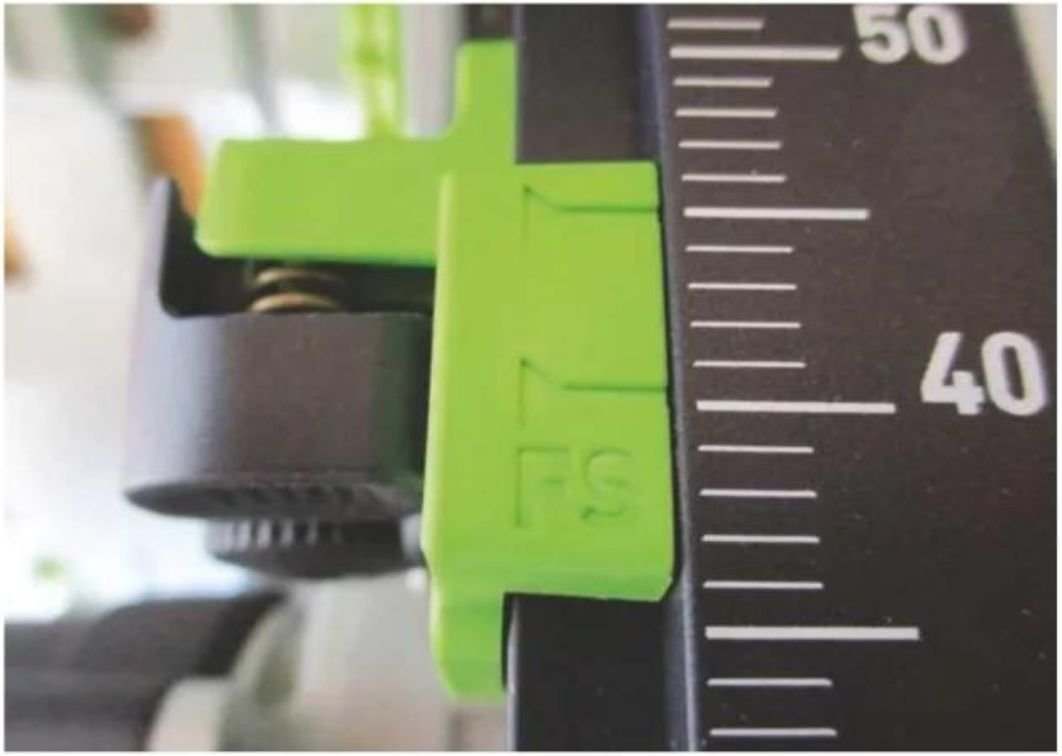

There are two markers for setting the required depth: with- or without-track. A ratchet allows the gauge to move down quickly, and you need to squeeze the lock button to move it up; depth can be set at 0.5mm intervals. The gauge is reliable, with a dial to correct it if slightly out, although double-checking you have the correct amount of breakthrough is always advisable. Maximum cut, at 90°, is an impressive 60mm.

The speed dial provides blade rotation control

Plunge lock for scoring wheel only

Depth gauge and scoring wheel adjustment

The blade key is stored under the saw’s cover

The scorer key is more exposed

Once you’ve set the depth and fixed the track to the workpiece, the saw can be placed behind the start point. Ideally, this will be clear of the timber’s edge, so that it doesn’t start cutting straight away, but sometimes you’ll need to plunge directly into the material.

Kickback time

Those who’ve pushed a rotating saw blade into wood too quickly will know all about kickback. The motor power can’t overcome the load suddenly applied; as the blade gets stuck, the motor, which is still turning, forces the saw back, up and out of the timber. As soon as the blade is released, unless you’ve removed the power, it’ll start spinning again…

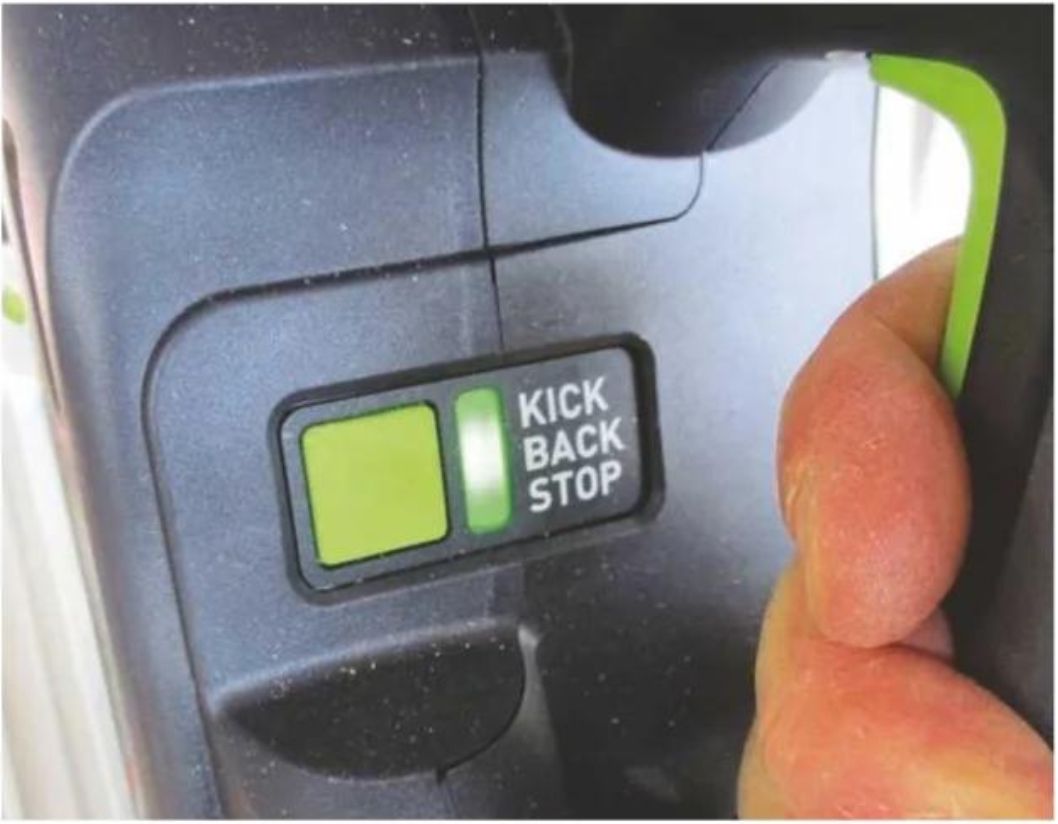

To prevent this, the TSV 60 KEBQ features a kickback feeler wedge – a steel plate located behind the blade. This disappears into the saw’s body when it comes into contact with a surface, i.e. when the blade is cutting the material; if the saw lifts at any point, either through operator action or as a result of kickback, the wedge drops and activates the KickbackStop system, instantly cutting off the motor.

KickbackStop can be deactivated if required, and there’s no need to risk material, track, saw blade or operator to check that it works; a built-in test routine with visual and audible signals can be run at a few touches of a button. DIY users or those with less track saw experience would definitely benefit from this feature, although the TSV 60 KEBQ-Plus is classed as a professional-level machine.

Measure the thickness…

Chip-free

Another aspect that sets this saw apart from the competition is its diamond wheel scorer. This can be used for all cuts in wood, laminates and certain solid plastic sheets whenever splintering or chipping of the cut’s top edge is likely, especially if there’s an impact on appearance, when connecting two pieces of laminate at an angle for a kitchen worktop, for example.

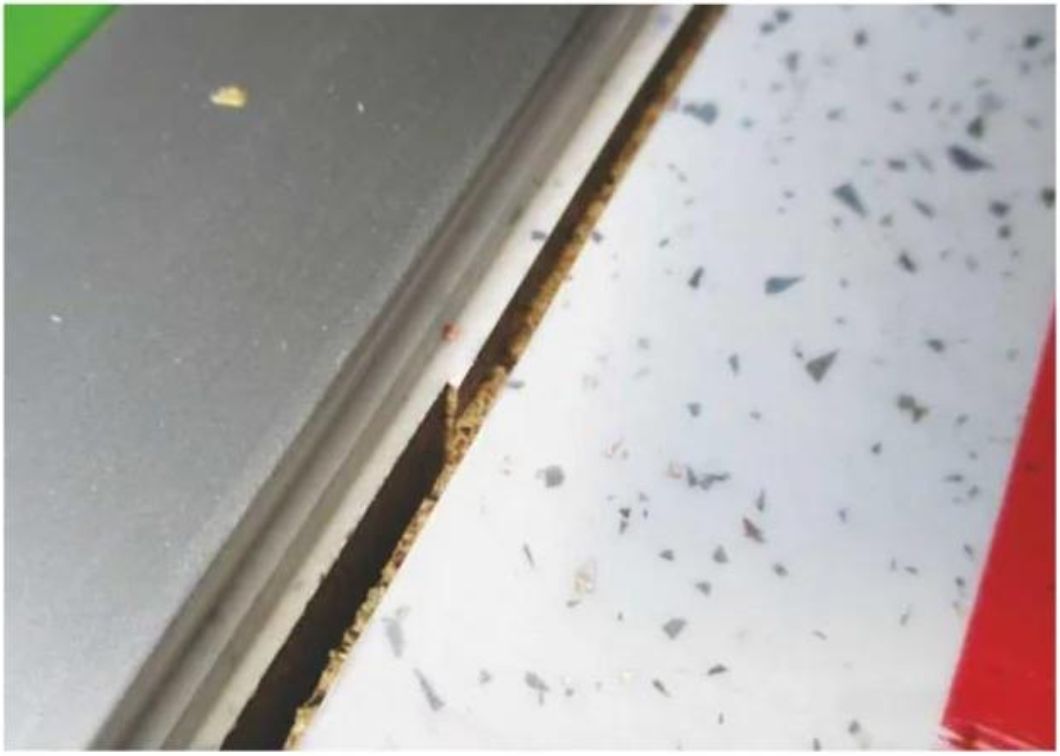

The scoring blade must line up with the side of the blade that creates the finished edge, if you’re simply cutting an end, or be set to score a kerf the same width as the blade if you want both sides of the cut to be clean and chip-free. My test indicated – very clearly – that it wasn’t set up correctly, so I began to try and work out how it could be realigned. One wheel provides left and right movement, and the other sets the depth at which the blade cuts into the surface; kerf width depends on the depth, since the scoring blade is tapered, although Festool describes it as ‘conical’.

It took a while to get this right, especially lining up the scoring wheel’s centre with that of the blade, which resulted in me wasting a few centimetres of laminate. Once set, however, it worked very well. The scoring blade mechanism is activated by pushing the lever up, and a follower pressing against the main saw blade housing moves the wheel down during plunging. Blades can be activated and deactivated independently, so three settings exist: just cut; just score; or both together.

Typical finish achieved using a track saw

… set up the depth…

Blade and scoring wheel set up

… FS = with track…

… which could cause problems if you get it wrong

Feeler wedge drops when the saw lifts

KickbackStop protection enabled

Scoring blade follower in place

Mitring

As with most track saws, the TSV 60 KEBQ can be set to cut any angle between 0-450. Although the scoring blade swivels with it, this needed to be readjusted as it was very slightly out; and unlike other track saws I’ve used, there’s no anti-tilt mechanism to prevent the saw from leaning over unless manually held down on the track.

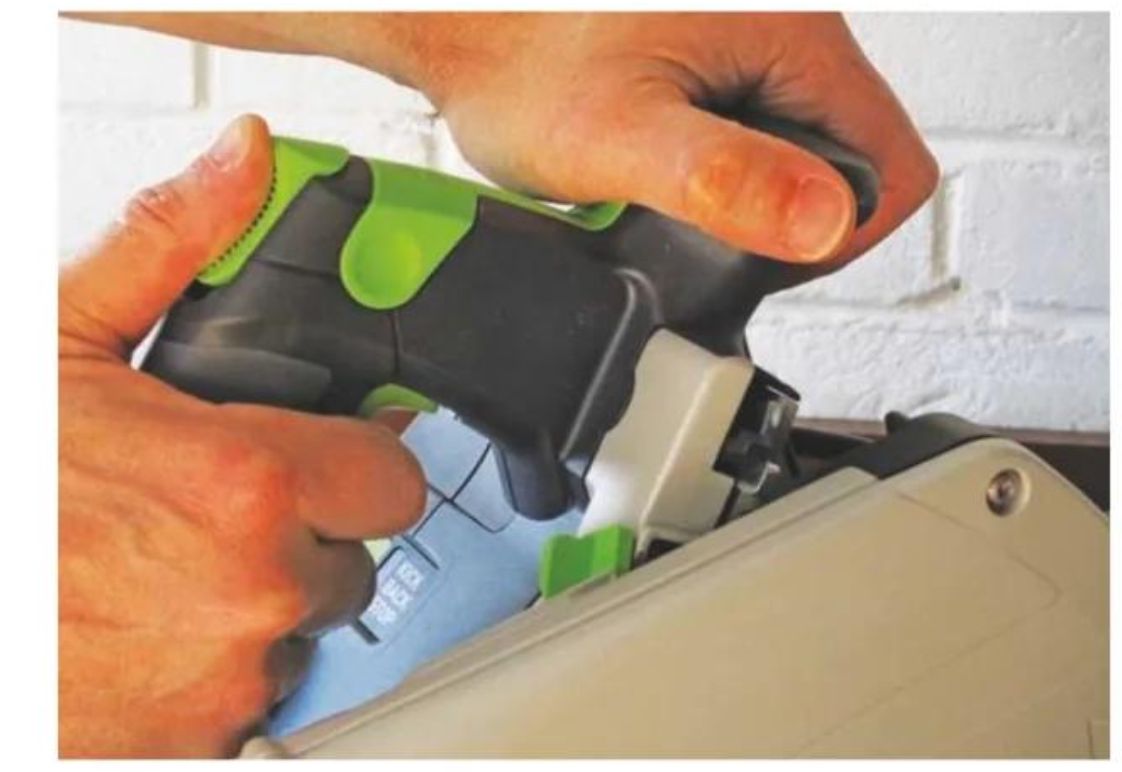

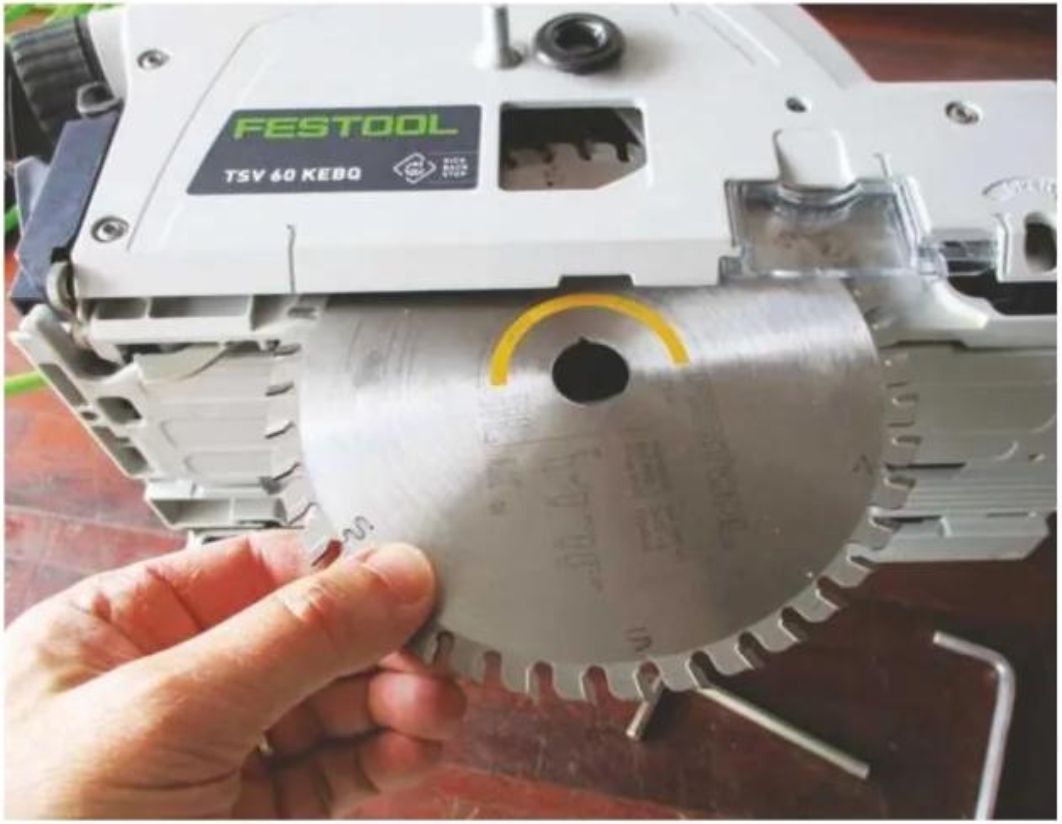

In case you’re wondering about the TSV 60 KEBQ’s styling, there’s a reason why the case is a tad boxy; this makes it easier to lie the unit on its side during saw blade changing: just unplug the saw, pull out the FastFix spindle stop – the appropriate green section of the handle – and push the blade down until it locks.

The fixing bolt lines up with the cut out so it can be undone with the supplied hex key, and the freed blade is simply slid out from the housing. The supplied blade has a yellow ring, indicating its suitability for wood and wood composite materials, including those with a thin laminate surface, but others are available: red for laminates; green for plaster or cement-bonded fibre-board; blue for aluminium and plastics.

Quality of cut following adjustment

Lift the FastFix lever in order to change the blade

Mitre adjustment lock

Plunge lock activated

There are a host of other features worth mentioning the base dials, which remove slack from track travel to ensure a straight cut; both sides of the base have guide arrows to indicate the main saw’s position and scoring blade, for easy alignment when cutting in from the edge – cutouts for sinks or other worktop inserts, for example; the powerful motor and thin blade make cutting easier; electronic braking stops the saw blade in around two seconds; the removable power cable facilitates easier Systainer – transit box – storage, and no electrical skills are required if it needs replacing. The saw can also detect over-heating during extended, continual use.

Conclusion

If workshop space is limited, or site-work is part of your everyday experience, track saws are a viable alternative to a table saw; you merely move the machine over the material as opposed to the other way round. The TSV 60 KEBQ is a very good example of this and, with its scoring feature, suitable for a wider range of materials than its competitors.

Once you know how the TSV 60 KEBQ works, it’s easy to use; there’s a quick setup reminder in the lid and Festool also supply a very detailed manual. In no fewer than 14 languages, it’s packed full of safety information and technical references, but couldn’t be described as easy reading! Manual diagrams are only printed once, most at the start and fewer at the back, so making sense of explanations is more difficult, as you have to keep flipping back and forth. I soon tired of the manual, and discovered a wide range of online videos which provided a much more user-friendly ‘how-to’ experience.

The scoring blade is no gimmick – it really does produce an excellent finish, when set up correctly. As I’ve found, this takes experience and, unfortunately, a certain amount of wastage for testing alignment, but it would be a useful timesaver for professionals fitting laminated board furniture day-in, day-out.

Blade held, spindle locked, retaining screw accessible

Simply undo the screw and remove the flange…

…and the blade slides out

One common criticism of the TSV 60 KEBQ is that, despite being a high-end machine, it’s not battery powered. I understand the argument for cordless power tools, although when used in conjunction with an extractor to control dust, which requires a hose, not being battery powered doesn’t really pose a problem. At 4m long, the power cable is sufficient for even the biggest of boards.

There’s the option of adding a passive box-type dust collector, in which case battery power would make more sense, but wouldn’t be as effective at picking up waste. The more powerful the motor, the bigger the battery capacity required – along with spares for when they go flat mid-job, which obviously adds to the price of what’s already a top-end machine.

In addition to the plunge saw, I also had the opportunity to try out one of Festool’s mobile dust extractors. While performing well and powerful in use, it didn’t pick up everything created with the scoring blade or saw, and a dust mask is definitely required. Purchasing Festool’s ABSA-TS55/60 guard does improve dust collection capability for some models, but, as yet, one isn’t available for the TSV 60 KEBQ.

In my opinion, these should be provided as standard, especially in the case of a machine designed for cutting plastics and cement boards.

Festool has a reputation for providing features and quality, with a price tag to match: in this case, nearly £ 1,000 for the saw, or £ 1,200 for saw and track, which is quite an investment. It could be argued that the TSV 60 KEBQ, with the backing of a three-year warranty, is worth the expense, especially if you’re a professional craftsperson, due to its ease of use, a powerful motor, and the ability to achieve an excellent finish in less time than other track saws on the market.

SPECIFICATION

| Product | Circular Saw/Scorer |

| Power Consumption | 1,500W (circular saw) / 190W (scorer) |

| No-load Speed | 3,000-6,800 min⁻¹ (circular saw) / 22,000 min⁻¹ (scorer) |

| Saw Blade Diameter | 168mm (circular saw) / 47mm (scorer) |

| Angular Range | 0-45° |

| Cutting Depth | 0-62mm |

| Dust Extraction Connection Diameter | 27mm / 36mm |

| Cable Length | 4m |

| Drive Type | Mains |

| Product Weight (without accessories) | 6.2kg |

| Transport Weight (including accessories) | 10.10kg |

| Includes | Allen key 4; flag window; vision panel; FS 1900/2 guide rail; WAF 5 hex key; 4m plug-it power cable; 47 x 2.5 x 6.35 T1 dia. scoring saw blade; SYS3 M 437 Systainer; WOOD FINE CUT HW 168 x 1.8 x 20 WD42 circular saw blade |

| Website | www.festool.co.uk |

VERDICT

When you purchase through links on our site, I may earn an affiliate commission. Here’s how it works.